Manufacturing companies successfully overcoming pandemic hardship invest 20% more into smart factory budgets, 2020 Deloitte and MAPI Study claims. The Fourth Industrial Revolution and AI in manufacturing transform the industry. This means that businesses must move faster to innovate the way their products are produced — from design to distribution. The good news? Manufacturing companies don’t have to struggle alone — there is always a helping hand for machine learning consulting. Creating AI ecosystems such as smart factories can support manufacturers facing ongoing disruption by building a competitive edge in efficiency and productivity. Thus, let’s dive into one of the components of this ecosystem, computer vision.

What is computer vision?

Artificial intelligence that understands images or video (by capturing, processing, and creating output) is called computer vision. In manufacturing, it uses input from production lines to elicit proper reactions and assist humans in various production-related tasks.

How is computer vision used in manufacturing?

Usually, computer vision in manufacturing is used for product and quality assurance, structure surveillance, and tracking for damages or faults. Cameras allow manufacturing plants to inspect their products for tiny defects. They can be much more sensitive than the human eye, and machines’ attention is never tired.

1. Productivity

Consumerization of high-quality products is growing, and the manufacturing industry aims to satisfy that needs with the same requirements for precision and consistency. Automation of production lines eliminates human error by assigning repetitive tasks of different difficulty to robots enhanced with computer vision systems.

Automated assembly

A computer vision system combines human sight and intelligence and the computer’s processing power for higher efficiency, consistency, and productivity. A collaborative approach to automation appeared to be more productive. For instance, machine vision inspection systems can flag flawed details for human auditors to check.

Tesla is an example of a highly automated manufacturing unit with humans and machines working together. In 2018, Elon Musk, CEO, claimed that “excessive automation was a mistake” and that “humans are underrated.” In complex environments, such as a smart factory, high adaptivity is essential to act in unforeseen circumstances or in situations with high input variability. As humans have adaptive intelligence, automation cannot entirely replace them. Thus Tesla re-designed their manufacturing processes to be more collaborative. However, it is vital to compare the results of computer vision systems with human equivalent to finding the most efficient solution.

Cycle time control

A machine vision system can learn and automatically measure the time of every production cycle. Moreover, manufacturers can deduce and isolate the best practice time of each cycle. When those periods significantly differ from the “golden standard”, it may mean deviations in the process. AI then alarms a human supervisor, who can watch the video to validate or fix the operation. Then spread the technique to reduce target time and meet tact time to fit the conveyor.

3D vision monitoring

The AI computer vision system builds an accurate production process model with visual data from cameras. If a detail does not fit the standard, the system can alarm the engineer to avoid flaws.

See how this 3D vision inspection and sorting production line operates.

Optimizing Supply Chains

Supply chain optimization helps reduce costs while enhancing customer satisfaction. For example, some manufacturers have implemented computer vision for warehouse management, managing inventories, and improving efficiency in the organization. Amazon and Walmart apply drone systems to monitor warehouse inventories. Next, real-time camera streams are processed by AI for empty container identification, thus restocking optimization.

Digital Lean Manufacturing

Increased productivity of a manufacturing operation while waste decreases could result from computer vision systems implementation. For instance, by leveraging a computer vision inspection system, the manufacturing industry may improve the measurements of processes efficiency and workload optimization across the plant floor. Another application is the early detection of equipment malfunction.

Experts from Deloitte estimate that the digital lean transformation will generate an improvement of US$20 million yearly in earnings before interest, taxes, depreciation, and amortization (EBITDA), decrease costs by 15% per line per year and improve general equipment effectiveness (OEE) by 11% yearly.

2. Quality inspection

Step verification

The AI computer vision systems can track every operation step and allow to go into the next stage after the previous step is approved, thus, resulting in fewer faulty items.

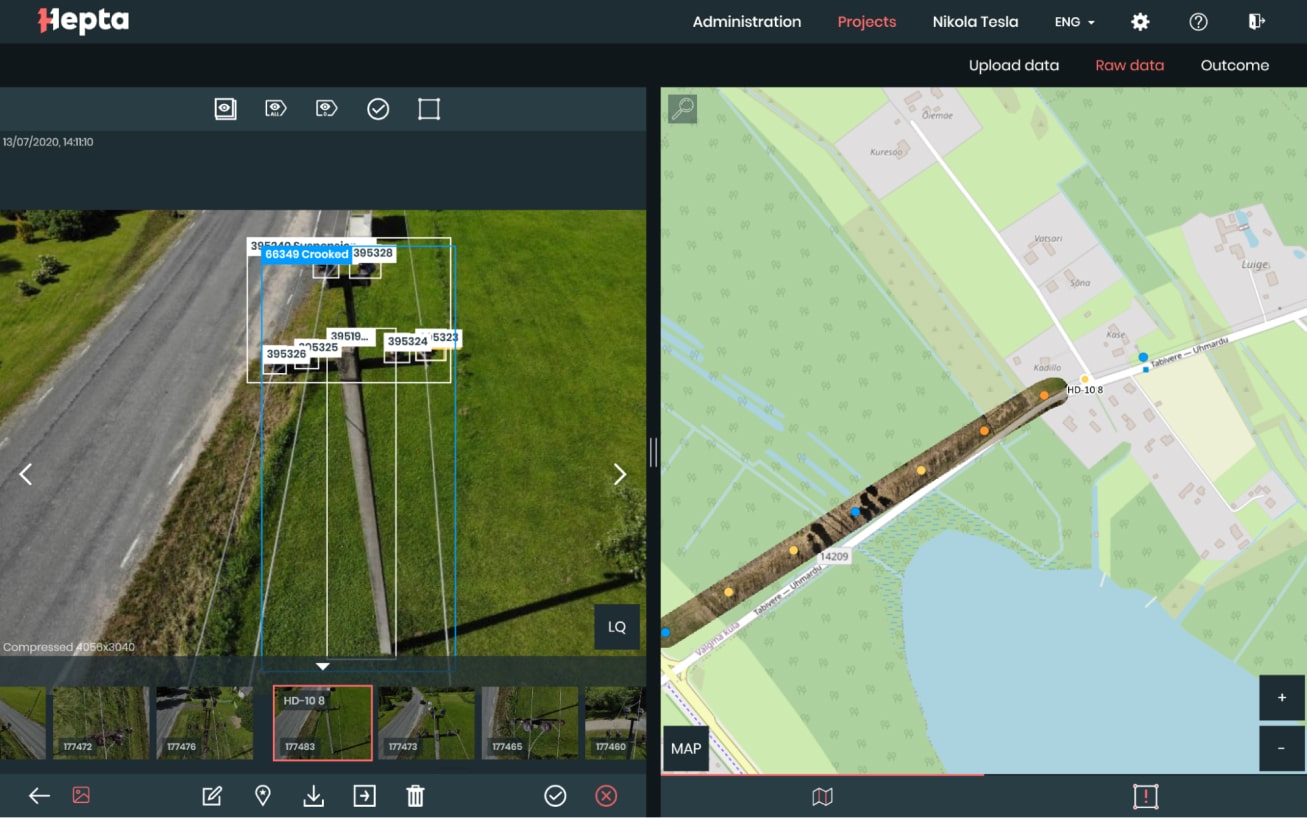

Anomaly detection

When integrated with machine learning-powered anomaly detection, computer vision facilitates automated visual quality control processes, identifying defective products by detecting any type of anomaly, such as scratches or dents. Hepta Airborn and MindTitan collaboration, described in the computer vision case study, explains this use case in detail.

Root cause analysis

A computer vision system records video of every operation of an assembly line provides the possibility to take any serial number and watch thoroughly what went wrong when the defective product was manufactured.

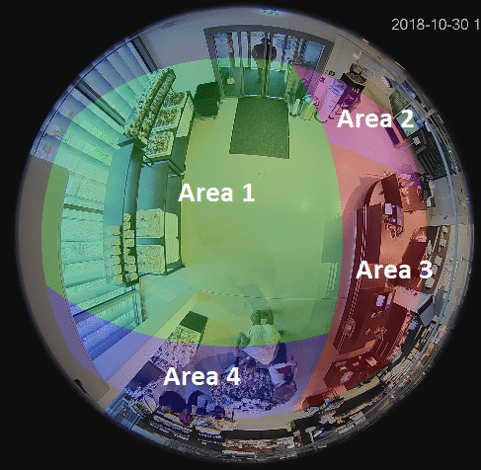

3. Safety

Computer vision helps object tracker in a video and detects them in an image, thus allowing businesses to enhance their security significantly. Visual data from security cameras can be combined with other data types, such as data from motion or IR sensors. These data can then allow the AI system to detect and track suspicious items or people moving within a particular monitored location and automatically send relevant alerts to the concerned authorities. Moreover, pattern recognition algorithms, processing video streams, or AI image recognition can flag violations of adequate dress codes for dangerous production.

COVID safety

The global pandemic added other concerns for the security departments: wearing masks or maintaining social distancing. Computer vision makes crowd monitoring possible. This technology has proven effective in detecting whether people have followed SOPs.

4.Factory synchronization and dynamic scheduling

Manufacturing systems (e.g., enterprise resource planning and manufacturing execution system) provide dynamic resource allocation and schedule. This system employs cameras and IoT devices to track material and product movement in real-time. In addition, those systems accumulate and use visual data for real-time tracking of material and product movement. As a result, agility improves, inventory reduces, and overall equipment effectiveness grows.

5. Predictive maintenance

Equipment downtimes can be expensive, thus leading to substantial losses. Computer vision technology can consistently and accurately monitor production machinery for the early signs of degradation. Reinforced with IoT and deep learning, these computer vision systems can be highly accurate and consistent. As a result, they can alarm engineers for maintenance before it is too late and the issue occurs.

Such giants as Royal Dutch Shell, ExxonMobil, and Chevron use AI predictive maintenance to watch their equipment for malfunctions.

6. Reading barcodes and QR codes

It is a popular computer vision use case in the manufacturing industry. Recognizing and reading barcodes and text is not an easy task to do every day. Smart factories use modernized artificial intelligence as well as computer vision-powered systems and applications to solve this problem and flag off green signals for industrial automation.

7. Training

Computer vision could be used as a part of a machine learning system to create a virtual environment for training and skill development.

Standardized work adherence and “mistake-proofing”

Following the same “golden process” every time is the key to manufacturing excellence. All line associates, no doubt, should be trained to use it. However, with its real-time video analytics, computer vision can ensure that steps are followed in the correct order on every cycle.

Full-fledged new operator training

The wealth of video data allows your best front-line workers to cross-train their colleagues with example videos and check the process with object tracking or image recognition.

8. Track-and-trace

Some manufacturers must track and trace their products from the production line to the client. It is especially crucial for fresh food and medicine.

Thus, packages can be marked with serial numbers, expiration dates, manufacturing dates, et cetera. A special code from a globally unique identifier, GTIN (Global Trade Item Number), allows tracking packages worldwide.

Manufacturers autogenerate these codes in a master database and use them later in the production process, printing those onto containers. The next step of the production process is verifying the information just sprayed onto the carton on the packaging.

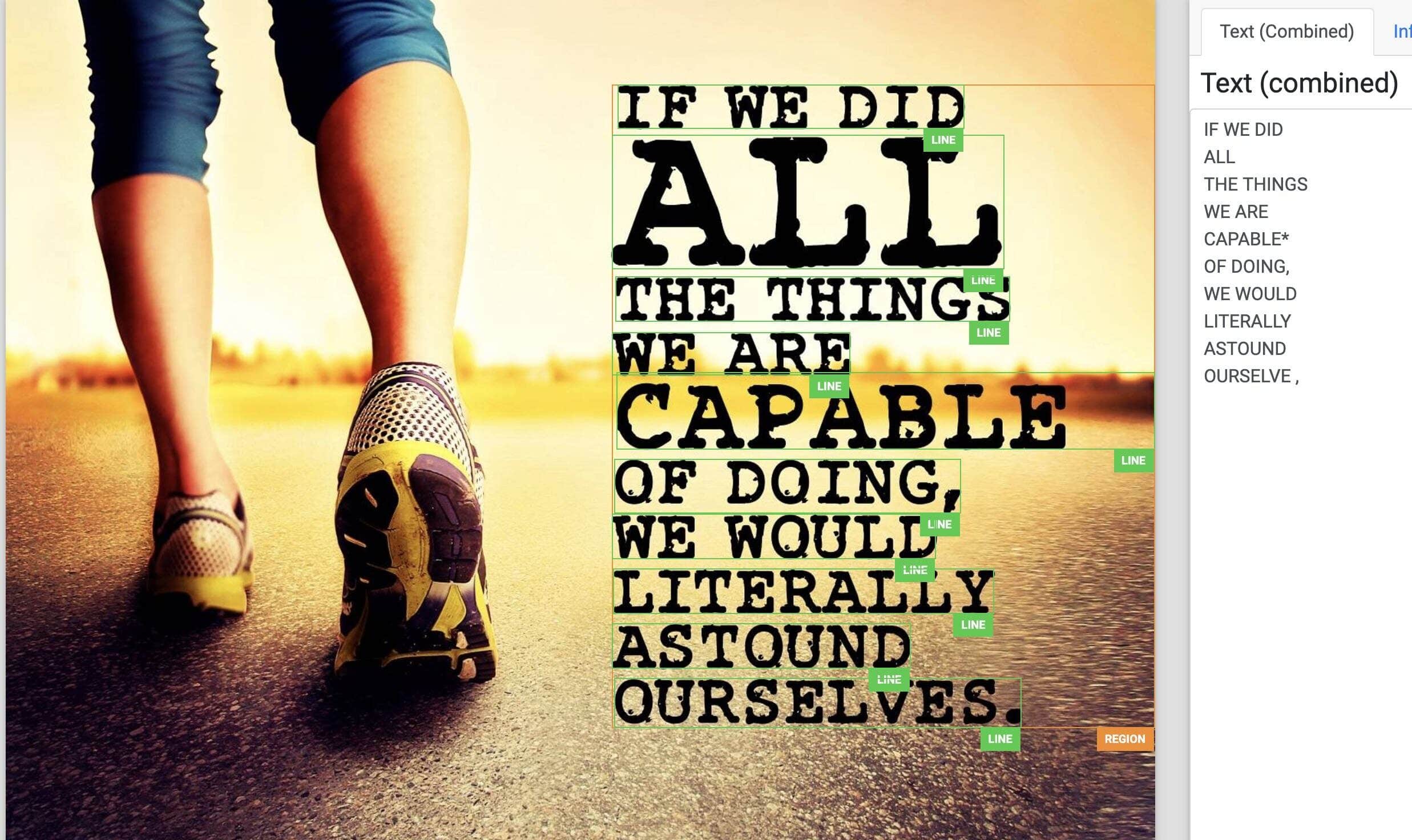

For instance, the computer vision system reads the printed text via high-tech cameras, recognizes it with optical character recognition (OCR), checks it in the master database, and then validates whether the printed label matches the stored data. Packages are rejected if any codes are indistinct or don’t match existing data.

9. Plain text reading and handwriting analysis

Even though optical character recognition (OCR) is nothing new, getting the machine to identify and extract text from images is entirely different. However, teaching a device to recognize text in an image can be a massive productivity boost.

For example, Microsoft has released technology in their Cognitive Services stack called the Computer Vision API. It can detect the presence of readable text and transform it into a stream of text.

Computer vision revolutionizes the supply chain.

As explained above, robots cannot entirely replace human intelligence in manufacturing plants. However, they can augment their performance for better outcomes. For example, the practice of using a cobot adds a team-based approach to a single-player machine. Thus, advanced computer vision techniques can keep people safe and optimize how a team of robots deals with tasks. Besides, video can be processed frame by frame or through spatio-temporal analyses. The benefits here are broad, but worker safety is the key benefit.

Human activity and advancing the front line

The analysis of video streams with computer vision can understand and optimize human movements within a facility as efficiently as a human engineer. This includes assembly analytics (a time study for every assembly cycle mentioned above), automated spaghetti diagrams, and social distance tracking. The primary value is improved quality and higher productivity of a manufacturer’s most significant asset — workforce.

Sustainability in manufacturing

Machines can look for patterns to determine whether an engine should run or can be idle, thus affecting maintenance efforts and energy usage. The same for chemicals; cameras are efficient in monitoring sulfur oxide (SOx) and nitrogen oxide (NOx) emissions by checking the color of the water to determine the presence of pollutants. On top of that, the usage of machine vision for quality control decreases scrap that cannot be reworked and ends up in landfills.

Thus, computer vision reduces scraps and consumption concerning energy, chemical usage, air quality, and raw materials.

Revenue impact

Furthering the topic of sustainability, reduction of energy or chemical consumption delivers lower costs. The logical consequence of AI optimization is revenue growth: maximized first-pass quality can increase yield or reduces scrap, saving money on raw materials.

By embracing computer vision systems, manufacturers can better assure quality and monitor equipment and worker safety. Thus, it helps to adapt to outside disturbance variables and continue to operate smoothly under almost any circumstances.

Any barrier to using computer vision platforms?

Indeed, modern machine vision has a barrier to entry. Without a background in computer vision, it can be challenging to understand where to start. The usual first question is: to build custom or buy the ready solution? Unfortunately, only a few well-established catered solutions for the manufacturing industry utilize modern computer vision. Thus, buying could not be an option for anything exceeding the simplest use cases.

That said, modern computer vision in manufacturing requires a considerably diverse skill set (machine learning, software development, computer science) from the team aiming to build in-house solutions. Moreover, the manufacturing sector is still controlled by the old hat, and innovations are hard to come by, making the building option challenging to pull off. Thus, if your company turned to the new era of ML automation, it might be a good idea to check out and hire outsourced experts in computer vision development.